Engineered for success across both LEO and GEO missions

Compliant with stringent airworthiness standards for structural integrity, environmental conditions, EMC, MTBF, DO-254, and MIL-STD.

Specific risk management, traceability, and regulatory compliance tailored for the global Aerospace & Defense industry.

After leaving Bharat Electronics in 1985, NK Nehra founded NKE Group with the vision of acting as a gateway for superior technology to India’s fledgling defence industry. With a focus on space, aerospace & defence Mr. Nehra was able to amass a wide variety of customers, introducing his principals into critical & prestigious programs. His efforts resulted in a felicitation by the Queen of England, winning the Queen’s Award for Exports for Filtronics (now Teledyne Microwave).

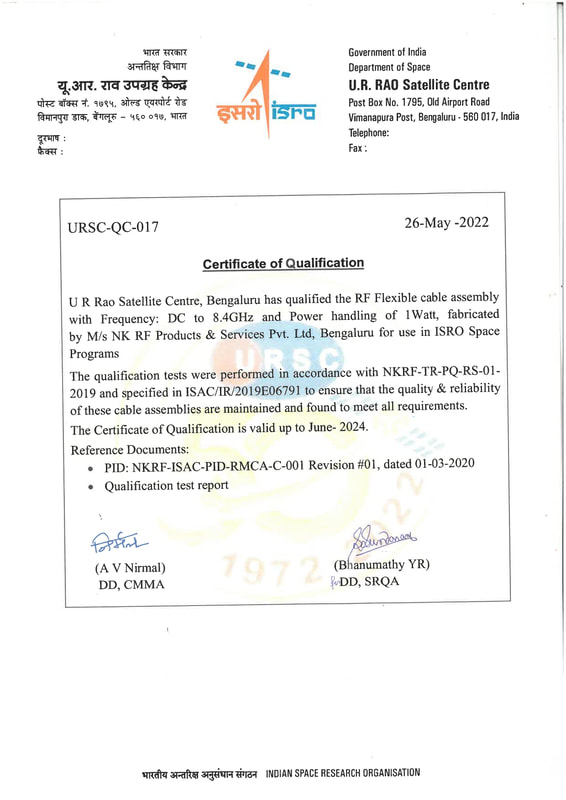

In 2011, Meenal Nehra Sood, our current MD pivoted from a single business line of representation to establishing an RF lab for cable assemblies upto 40GHz through NKRF. With support from America’s Insulated Wire, NKRF has grown into India’s sole indigenous manufacturer or airworth & space worthy cable assemblies. Under Meenal’s leadership, NKRF has grown strength to strength and is now a part of multiple programs contributing to many of India’s programs across fighters, helicopters, missiles, ground & naval radars, and more. NKRF’s world class quality has begun to be recognized by customers in the Europe & Middle East – with our cable assemblies flying in LEO space missions under ESA compliant satellites.

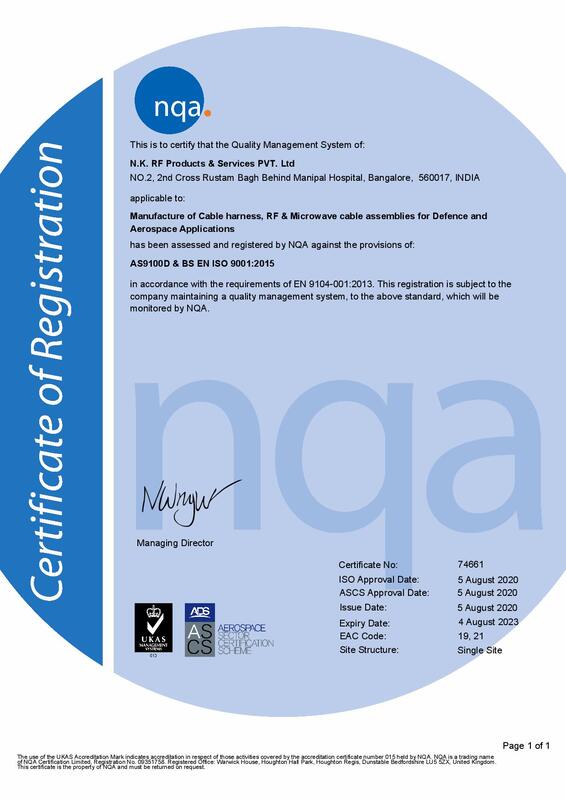

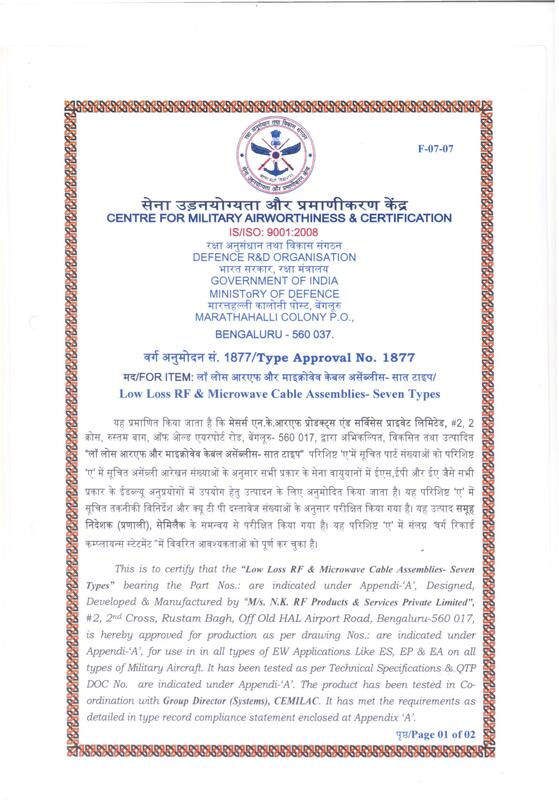

NKRF is reputed for it’s capability in phase and amplitude matching, quality standards in line with AS9100D, and it’s service capabilities providing rapid TAT for even large batches of assemblies. Our achievements include 500 assemblies in 3 days for low-loss cable assemblies, repair of airworthy cables in 24 hours, and getting qualified by India’s centre for military airworthiness, the honour of which is bestowed upon select manufacturers.

Challenge: DefenceCo’s system required DC to 18 GHz operation, but a design flaw limited the adaptor to 11 GHz. Redesigning would cause a 12+ month delay.

Solution: NKRF engineers leveraged a 70mm flexibility in the system to create a right-angle, phase-matched adaptor with a 65mm cable—meeting specs despite phase-matching challenges.

Impact: Delay reduced from 12+ months to under 2 weeks, ensuring an on-time launch.

Challenge: DefenceCo faced supply risks for an imported Y-cable assembly with no design transfer agreement.

Solution: NKRF engineers co-developed a new design from scratch, using iterative prototyping to deliver a solution in under four weeks.

Copyright © 2011 N.K.E Group. All Rights Reserved.